Contact: Manager Yang

Hotline: 950-4048-3964 (free)

Tel: 0510-85386636

Mobile: 18011518665

Shangmeng Technology Wuxi Co., Ltd.

Address: A1-602, Tianan Smart City, No. 228 Linghu Avenue, Xinwu District, Wuxi City, Jiangsu Province

How to prevent the aircraft wing and the car windshield from being icing and bonding may be something that many engineers are studying. For example, a team uses carbon nanotube coating materials to prevent the aircraft wing from being frozen when flying at high altitude by current heating. . However, there may be a better way to start today. Researchers at the University of Michigan have invented a rubber coating that can easily prevent icing from sticking to the surface of an object that needs to be protected, as shown in the following figure:

The left part of the above picture was left untreated. After a period of cold outdoor, it was found to have a layer of ice bonded, while the right part was sprayed with rubber paint (elastomer paint) and lost enough adhesion to the ice. The ice cube cannot adhere to the coating by its own gravity, so that the surface of the object remains clean. As can be seen from the above figure, this rubber coating has good transparency. In addition, the coating is lightweight and durable, and is very suitable for outdoor equipment that prevents icing, such as airplanes and automobiles. It is understood that the preparation of this coating is not expensive (and indeed not high, one of which is PDMS ) and is expected to be commercially used within one year.

So how does he work?

The aircraft is flying in high altitude and low temperature environment, facing the problem of easy freezing. The common solution is:

1, the engine heats up and dissipates anti-icing,

2. The outer surface of the aircraft is coated with anti-icing chemicals.

3. The outer structure of an aircraft that produces a superhydrophobic surface,

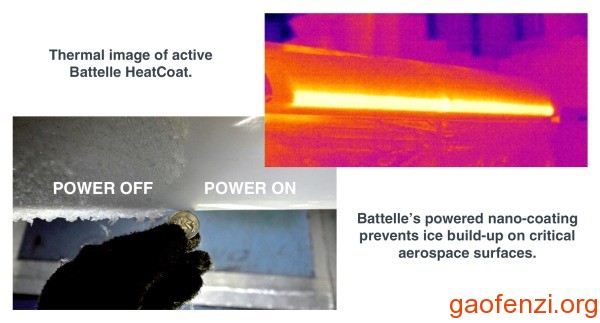

Recently, Battelle researchers developed a carbon nanotube (CNT) heating coating technology ( BATTELLE HeatCoatTM ) to help the aircraft resist ice formation . The schematic is as follows:

The aircraft casing involves a total of four coatings, in which the carbon nanotube coating generates heat by the power source, and the temperature of the surface of the aircraft in a cold environment is improved to achieve an anti-icing effect, which is due to trade secrets. The composition of the various materials is unknown.

According to Battelle, this coating technology is lighter and easier to use than other aircraft anti-icing techniques. This technology has successfully achieved anti-icing by unmanned aircraft at a speed of minus 30 degrees Celsius with a four-day flight test of 337 km/h. In the following figure, in a cold environment, when connected to a power source, the coating heats up to prevent ice formation, and when the power is turned off, it freezes on the aircraft casing in a cold environment.

Source: Polymer Network

Previous: Application of superhydrophobic coatings

下一条: Industry people teach you how to choose an air purifier, used to say reliable (2)

Address:Tianan Smart City A1-602, No. 228 Linghu Avenue, Xinwu District, Wuxi, Jiangsu, China TelePhone:0510-85386636 Fax:0510-85384339 E-mail:info@solmontech.com

KeyWord: